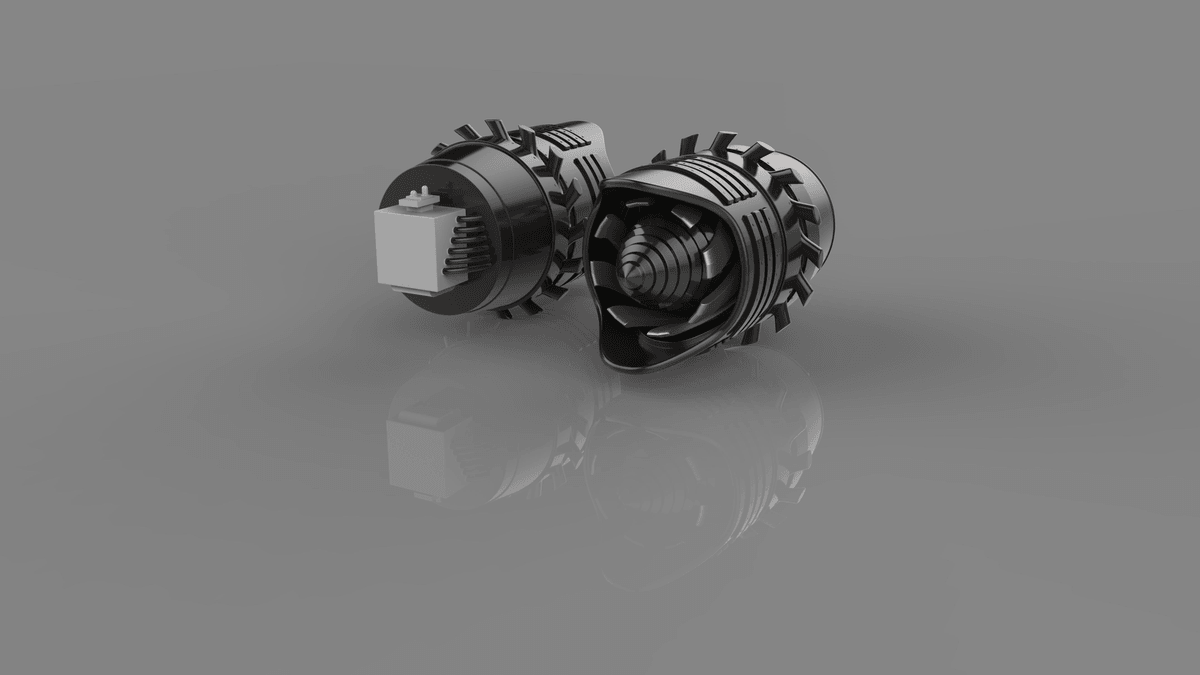

Choosing a smart motor is an important decision for businesses aiming to enhance efficiency and reduce operational costs. Smart motors, equipped with advanced technologies, offer significant advantages over traditional motors, such as improved energy efficiency, enhanced control, and predictive maintenance capabilities. Here's a comprehensive guide to help you choose the right smart motor for your needs.

First and foremost, it's essential to understand the specific requirements of your application. Different applications have varying demands in terms of torque, speed, and load conditions. Assessing these requirements will help you determine the appropriate motor specifications, such as power rating, voltage, and current capacity. For instance, industrial applications like conveyors, pumps, and fans may require motors with higher torque and robust construction, while HVAC systems might prioritize energy efficiency and quiet operation.

Energy efficiency is a critical factor in choosing a smart motor. Traditional motors can be highly inefficient, leading to increased energy consumption and higher operational costs. Smart motors, on the other hand, are designed to optimize energy usage through advanced control algorithms and real-time monitoring. Look for motors with high-efficiency ratings, such as those compliant with the International Electrotechnical Commission (IEC) standards or the National Electrical Manufacturers Association (NEMA) efficiency classes. Additionally, some smart motors feature variable speed drives (VSDs) that adjust motor speed based on load conditions, further enhancing energy savings.

Another important consideration is the control and connectivity features of the smart motor. Modern smart motors often come with built-in sensors and communication interfaces, enabling real-time monitoring and remote control. These features allow for predictive maintenance, where potential issues can be identified and addressed before they lead to costly downtime. Look for motors that support common industrial communication protocols such as Modbus, Ethernet/IP, or Profibus, ensuring seamless integration with your existing automation systems.

Durability and reliability are crucial when selecting a smart motor. Motors used in industrial environments are often exposed to harsh conditions, including dust, moisture, and extreme temperatures. Ensure that the motor you choose has a robust design and is rated for the specific environmental conditions of your application. Features such as sealed enclosures, corrosion-resistant materials, and high thermal ratings can significantly extend the motor's lifespan and reduce maintenance requirements.

Cost is always a significant factor in any purchasing decision. While smart motors may have a higher upfront cost compared to traditional motors, their long-term benefits often justify the investment. Consider the total cost of ownership, which includes energy savings, reduced maintenance costs, and extended motor life. Some smart motors also qualify for government incentives or rebates, further offsetting the initial expense. Conduct a cost-benefit analysis to determine the payback period and the potential return on investment for your specific application.

When choosing a smart motor, it's also important to consider the manufacturer and their reputation in the industry. Established manufacturers with a track record of producing high-quality, reliable motors are often a safer choice. Research customer reviews, ask for references, and consider the availability of technical support and after-sales service. A manufacturer with a strong support network can provide valuable assistance during installation, troubleshooting, and maintenance. For more info about the smart motor turntid, click here.

Scalability and flexibility are additional factors to keep in mind. As your business grows or your application requirements change, you may need to upgrade or modify your motor systems. Choosing a smart motor with modular design and expandable features can simplify future upgrades and ensure that your investment remains relevant. Some smart motors offer programmable logic controllers (PLCs) or firmware updates, allowing you to adapt to new demands without replacing the entire motor.

Finally, environmental sustainability is becoming an increasingly important consideration for businesses. Smart motors that reduce energy consumption and lower carbon emissions contribute to a greener and more sustainable operation. Look for motors with eco-friendly certifications or those that support renewable energy sources.

In conclusion, choosing a smart motor involves careful consideration of various factors, including application requirements, energy efficiency, control features, durability, cost, manufacturer reputation, scalability, and environmental impact. By evaluating these aspects and conducting thorough research, you can select a smart motor that not only meets your current needs but also supports your long-term operational goals.